Laser cutting is becoming increasingly popular for creating sheet metal parts. It is the process of using a high-quality fiber laser to cut metal to precise specifications. This method is often favorable towards other machine cutting techniques due to their ability to reduce production costs for manufacturers. Many factors of laser cutting reduce production costs, including efficiency, less material waste, and minimal post-processing. Below, we have detailed how Edge Metalworks’ laser cutting reduces production costs.

Increased Efficiency

Time is an essential factor in laser cutting. Lasers cut metal faster than other techniques; their speed allows for rapid turnaround times. Edge Metalworks uses fiber lasers, which will cut faster than CO2 lasers. Fiber lasers allow for shorter lead times that will reduce the cost of production. The accuracy of laser cutting completely outpaces other cutting methods, giving it a competitive advantage over other forms of sheet metal cutting. It allows for precise, consistent, and versatile parts manufacturing. Its accuracy also allows for easier welding and fabrication, as you spend less time welding and lining everything up like you would with plasma-cut parts.

Automated Systems

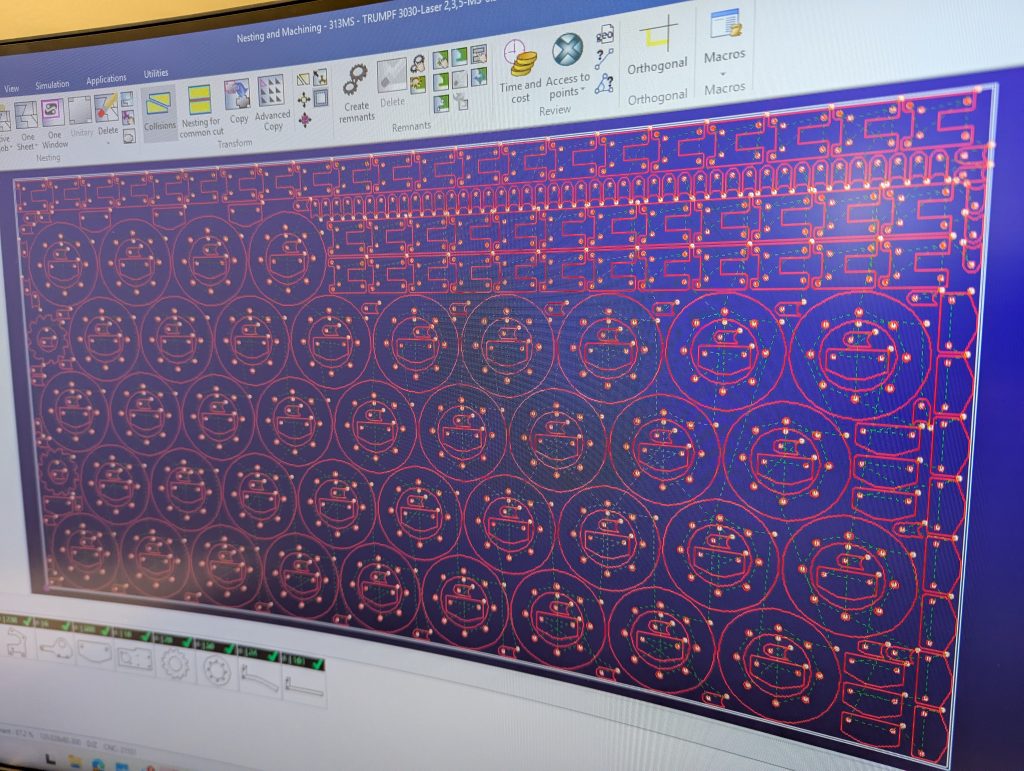

To increase efficiency, laser cutters use the latest automated systems like CAD, programming software, and machine automation to streamline the process. Our lasers have direct connectivity to a drawing platform that will send the design to the machine that cuts the metal precisely to the specifications. If you want to change the drawing, you can easily update it in the software. You only have to adjust the drawing, then the laser will cut the parts. There will be no costly tooling changes or downtime to reconfigure templates. Additionally, our programming software allows us to nest parts closer together, and even within each other, to have greater efficiency in material usage, thus lowering costs. The integrated software allows fewer production errors from the computers and machines, which will reduce your production costs.

Repeatability

Laser cutting also saves money with its repeatability. When you place an order, then realize later you need more of the same part, you can simply place another order, and our machines will have your drawing saved. There is no downtime for machine setup and no long wait times for redrawing the parts. You can create multiple exact copies of the same parts, allowing for uniformity in production.

Less Material Waste

The narrow kerf (width of cut) of lasers minimizes wasted materials, making this method better for cost and the environment. Traditional cutting methods often leave behind scrap pieces, but lasers use precision technology that reduces the amount of material waste. They leave behind clean cuts, optimizing material use, which will save on material costs in the long run. You can also order products in bulk with laser cutting, reducing the costs per unit.

Reduced Labor Costs

There is less human intervention needed with laser cutting, therefore, labor costs are reduced. They can handle intricate designs without the need for manual adjustments. Our automated systems require less human intervention for material handling, machine operations, and quality control. This reduces the need for skilled labor and minimizes human errors, resulting in decreased rework and labor expenses.

Less Energy Consumption

Lasers consume considerably less energy than older types of laser cutting methods, like machine cutting. Edge Metalworks’ fiber lasers even consume less than half the energy than CO2 ones. The energy efficiency and environmentally friendly practices of laser cutting will reduce your utility costs.

Minimal Post-Processing

Laser cutting requires fewer additional finishes, like needing to sand down rough edges or burrs from machine cutting. They produce accurate, clean cuts that ensure a high-quality finished product. The precision technology reduces the time needed for secondary operations, reducing post-processing costs and resources.

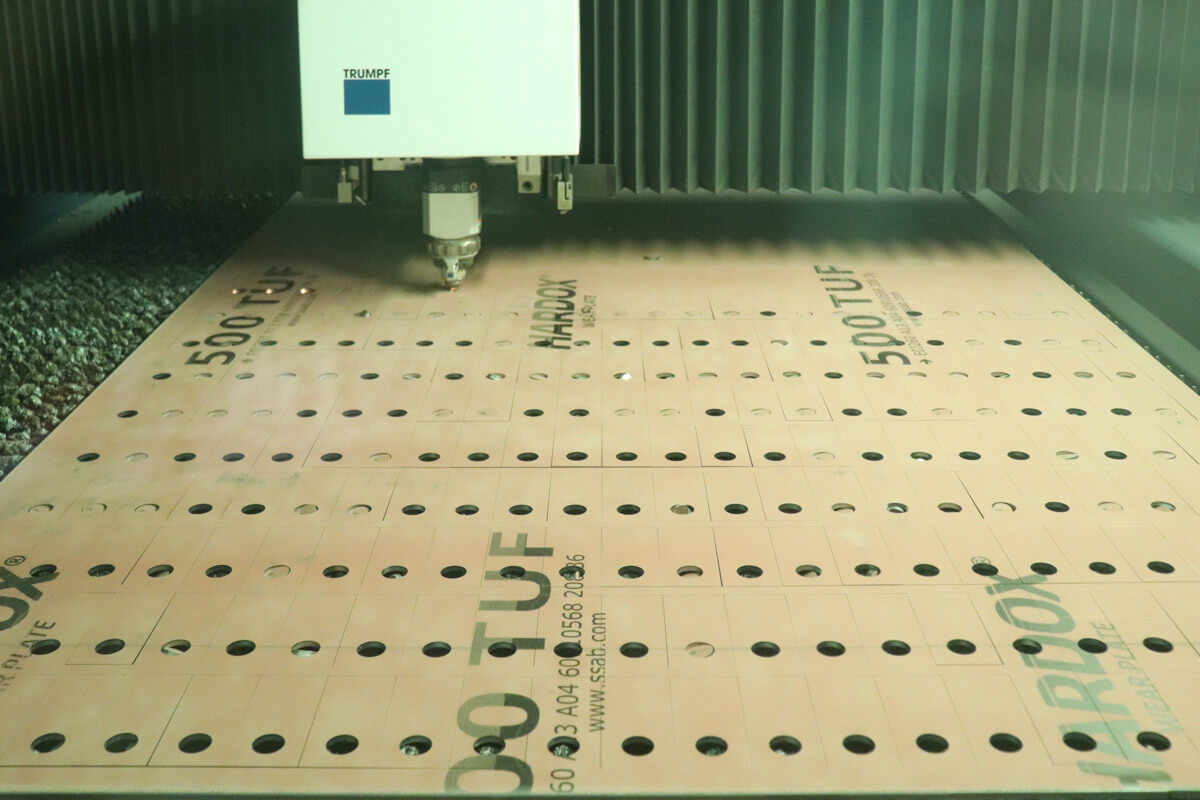

Get Laser-Cut Metal with Edge Metalworks

Sourcing your parts from laser cutting shops like Edge Metalworks can help reduce costs even more. One-stop shops often require additional costs because they don’t have the volume of production to allow for affordable laser cutting services. Laser cutting service shops focus strictly on cutting and forming, which allows us to focus on mastering this aspect of manufacturing instead of all of them. This also allows us to invest more heavily in new technologies in our industry, like our TRUMPF TruLasers. They improve production speeds and accuracy, which relates to the customer in the form of cheaper, more accurate parts.

Edge Metalworks serves many different industries and can cut hundreds of varieties of sheet metals specific to your needs. Contact us today to get started.