Consistency and correct measurements requested by clients require attention to detail and expertise in the entire laser-cutting process. In order to manufacture superior products, laser technicians and operators must know how to make adjustments for different materials and their properties. Read on to learn why choosing a laser-cutting team with experience and expertise is important for your business and products.

Mathematical Knowledge

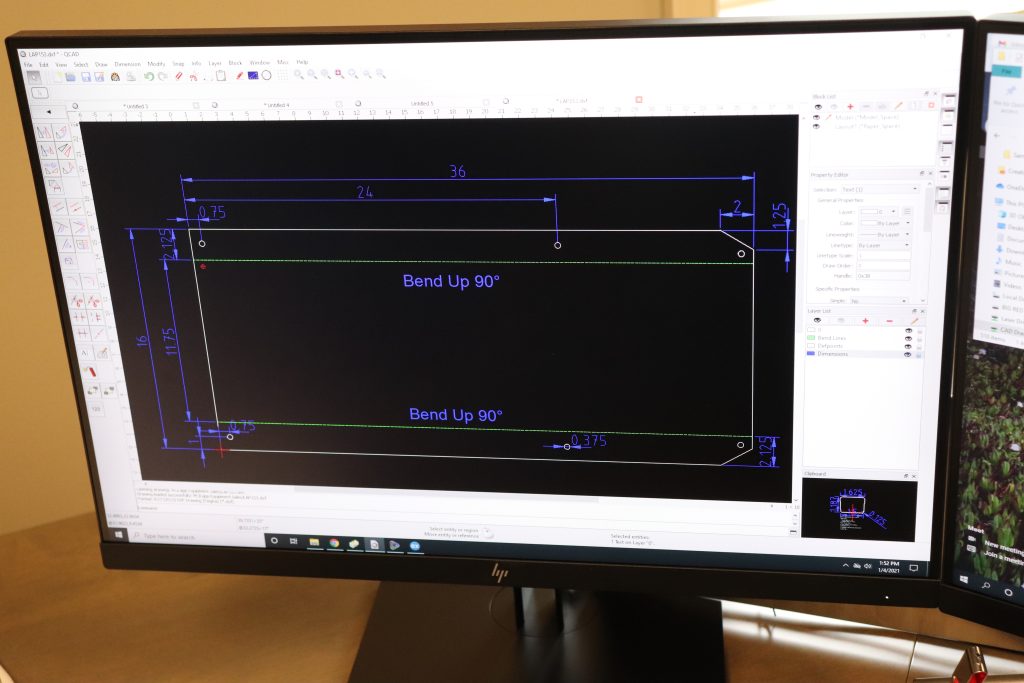

Laser operators and technicians must have an applied understanding of industrial mathematics, a way of solving business problems with math, and the ability to create physical products from blueprint instructions with a knowledge of different material characteristics. They must be well-versed in various units of measurement and able to adjust equipment settings based on their workspace and product materials. To put it simply, laser technicians and operators must have an understanding of geometry and mathematical problem-solving that they’re able to apply in the workplace.

Laser Speed & Metal Thickness

All manufactured pieces will not be cut at the same speed. Operators and technicians must be able to adjust speeds, cutting gases, nozzles, etc. based on material thickness and metal types. Correct adjustments are needed to ensure that finished pieces are smooth and free from snags or burrs. Laser speed is important for keeping pieces precise and consistent. If an operator or technician doesn’t adjust the lasers correctly, materials and time will be wasted. Expert operators and premium machinery result in high-quality products that are the same across the board.

Quality Control

Throughout the whole process, and especially at the end, laser cutting requires close attention to detail and review. Laser operators need to routinely inspect lasers and cutting equipment to ensure they stay in good working order and can continue to create consistent pieces. They need to conceptualize how a piece will work and if all details, like edges and angles, perfectly line up with their client’s requests.

For example, there shouldn’t be any signs of melting or burning on the pieces, which can be caused by improper machine adjustments. Likewise, completed cuttings should be smooth and have clean edges to avoid injury while handling the pieces. Quality control is important as even the slightest deviation in a metal piece can change the final product’s functionality.

Continued Learning

Laser cutting is a field that is always advancing. Operators and technicians need to be comfortable working with technology and staying up-to-date on the latest lasers and breakthroughs. Because this field is constantly evolving, these companies must be ready and willing to learn new tools and techniques. The best laser-cutting companies and metal manufacturers aren’t afraid of change. These teams focus on continuous improvement and growth among individual employees and the company as a whole.

While some companies will pass off bends that are within a few degrees of the requested angle, Edge Metalworks is dedicated to providing the most accurate and repeated products. Forming sheet metal is essential to many industries, so measurements need to be accurate for the continuation of high-quality functionality. There is no room for “good enough” in the metal bending industry. We believe that if a client needs pieces with 90-degree angles, all delivered pieces must be within the tolerance, no more and no less.

Ready to work with our innovative and industry-leading team? Get started today by contacting us to receive your free estimate. Engineering something? Ask our experts for input on designs for easy and competitive manufacturing which will improve quality and save money in production.