Warehouse Management Systems (WMS) are software that give control over all warehouse operations. Integrating these systems with laser-cutting technology optimizes your production turnaround. Laser-cutting from Edge Metalworks is very beneficial in the material handling industry, as it keeps everything moving at an ample pace. Using laser-cutting technology will help improve the efficiency of warehouse management systems and your overall operations.

What are Warehouse Management Systems?

A Warehouse Management System is a software that controls all the day-to-day aspects of a warehouse to improve operational efficiency. It is a key component of supply chain management, organizing all tasks of the business in one software. A WMS works with receiving and storing goods, and has tools for picking and packing, utilizing resources, analytics, and more. It manages the goods and materials in a distribution center, from when they enter to when they leave the warehouse. Warehouse management systems require lots of on-the-ground hardware, from hand trucks to forklifts to pallet racking to automated stock picking systems. These all require laser-cut parts to provide the efficiency and accuracy required in logistics.

Impact of Laser-Cutting for WMS

Makes Manufacturing Equipment Easy

To manufacture equipment, laser-cutting is a vital practice. This equipment often needs detailed, complex metal pieces to ensure proper operation. Laser-cutting is the best way to get the parts you need to your specifications, as some designs can only be made with laser equipment. Its automation and quick turnaround capabilities make it an ideal choice for cutting and forming the materials a manufacturer needs for equipment. The WMS will manage the company’s inventory, making it easier to find the specific laser-cut part they’ll need to create industrial pieces and equipment.

Automation

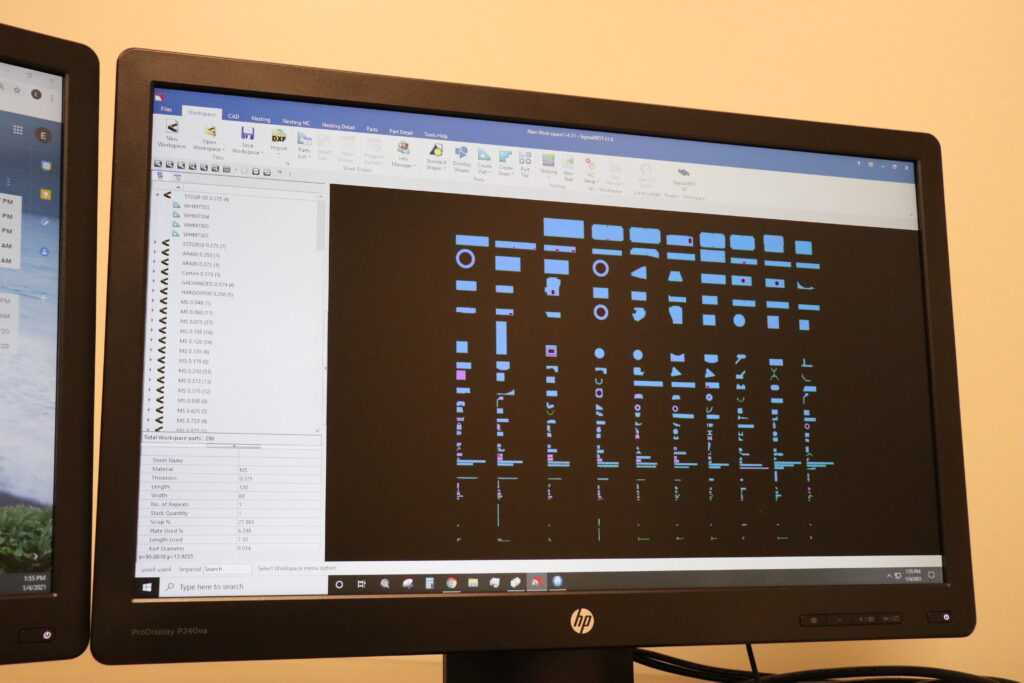

Everything in laser-cutting is automated; we can easily create multiples of the same piece with a CAD design. If your warehouse needs a large order of the same laser-cut piece, we can easily make hundreds of the same design with no defects due to the reliability of our CAD software and lasers. Later, if you realize you need more of that particular piece, your design will be saved in our software to make more pieces easily. Laser-cutting optimizes all processes for the warehouse, ensuring that everything is accurate.

Quick Turnaround

Laser-cutting is a quick process that allows us to have a fast turnaround time for delivering materials to various industries. Post-processing is not needed with laser-cutting, making the process easier and operations more efficient. With our quick turnaround time, manufacturers will be able to have a quicker production time to get finished manufactured parts and equipment to clients.

Provides a Sturdy Place to Store Materials

Warehouses will often have a section to store their raw materials, usually on storage shelves. These shelves will need to be sturdy enough to hold heavy materials. They’ll often use laser-cut parts in their storage shelves to make them more durable. The pieces formed from our laser-cutting will be strong enough to safely hold the large items. Warehouses can sometimes use an automated storage system with their WMS to transport items to the correct location within their warehouse.

Get Laser-Cut Parts with Edge Metalworks

Edge Metalworks has multiple lasers to provide durable, high-quality, laser-cut parts for manufacturing and material handling companies. Our TRUMPF TruLasers are skilled at cutting sheet metal and tubes for many industries. If you have any laser-cutting needs, contact us today to start a quote for your project. We look forward to working with you.