Many manufacturing industries need cut metal parts for their equipment, which can be obtained at either a laser or machine shop. Laser-cutting shops, like Edge Metalworks, use highly innovative laser technology to cut metal. Machine shops use rotating cutting tools to cut metal. Multiple factors go into the final costs of the products made in these shops, including processes, materials, and final products. When considering all these factors, laser-cutting shops will be a more cost-effective choice. To help you understand how laser-cutting shops will be cheaper in the long run, here are the differences between laser-cutting shops and machine shops.

Processes

Laser Shops

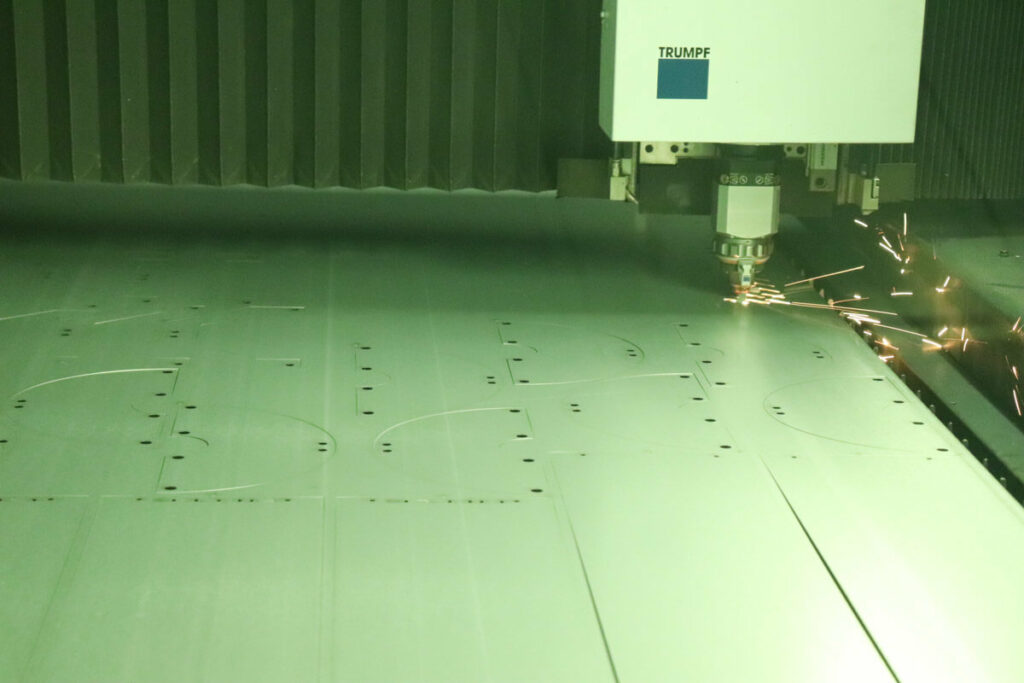

Laser shops such as ours use top-of-the-line, innovative laser technology to cut sheet metal. An intensified laser is used to superheat the metal, vaporizing it to make the shape you need. We fully automate this process with a Computer Numerical Controller (CNC) that guides the laser to cut a specific shape. Laser cutting is more precise than machine cutting, the laser technology allows us to produce accurate cuts with a quick turnaround.

Machine Shops

Machine shops use different cutting tools to shape materials, including turning, milling, drilling, sawing, and grinding. These tools are chosen depending on your desired final product, but they are all used to cut sheet metal. Machine shops also use CNC machines to automate the process and produce complex shapes. The difference is that machines take more time to create precise pieces than lasers do.

Materials and Equipment

Laser Shops

Our laser technology uses smaller and more intricate materials for our machines, including the laser, a fiber optic cable, and a nozzle with special lenses. Our CNC equipment guides the nozzle with the hot laser beams across an automated design path. These materials and equipment make the laser-cutting process faster and more precise.

Machine Shops

Machine shops use materials that can withstand high temperatures to be able to cut the metal. Generally, they use high-speed steel materials with rotating equipment to cut and shape the sheet metal. The machine uses friction from the rotating cutting tools to cut the piece. This practice allows these machines to work with denser materials.

Cost and Maintenance

Laser shops

Laser-cut metal often has a higher initial cost, but there are a few factors that bring down the overall cost in the long run. At Edge Metalworks, we use specialized machines that cut down on costs. Laser cutting doesn’t have as many wasted materials, which will bring down the overall cost of the product. It uses a uniform cutting tool, light, to cut the metal, so there is no extra cost to acquire the proper tools.

Machine shops

Even though the cost of machine cutting is generally less expensive than laser cutting, machine cutting has a lot more material waste. Machine-cutting tools also have a lot more moving parts than laser cutting, making them more difficult to maintain and clean. They also need specially shaped tooling to cut particular designs. These factors can be reflected in the cost of the pieces, which makes laser cutting a more cost-effective option overall.

Both laser shops and machine shops have their benefits, but generally, a laser shop is the go-to for sheet metal cutting. A machine shop is better for cutting items out of blocks of metal, which lasers simply wouldn’t be able to do. Machine centers will also create 3D parts, such as a crankshaft for a vehicle, where lasers wouldn’t apply. For any sheet metal cutting and forming, work with a laser shop like Edge Metalworks.

Get Laser-Cut Parts with Edge Metalworks

Edge Metalworks can meet all customers’ metal-cutting needs with our high-tech lasers. We invest in machines that best accommodate your needs, including the TRUMPF TruLaser 5030 which can work with a variety of metals including stainless steel, aluminum, copper, brass, and more. We also have the TRUMPF TruLaser Tube 7000, which can precisely cut metal tubes. Get precise laser-cut metal with a different level of professionalism with Edge Metalworks. Contact us today to get started with your project.