Laser cutting is the process of using a hot laser to cut various metals into detailed two-dimensional pieces. Laser cutting is beneficial for many different industries, but has revolutionized the agriculture industry. Laser cutting’s precise technology has evolved agriculture processes, making producing equipment a fast and efficient process. Here is how Edge Metalwork’s laser-cutting technology benefits modern agriculture.

How Do We Use Laser Cutting In Agriculture?

Laser cutting produces high-quality components for equipment used during peak farming season. Peak farming season is generally from September to December for the harvest, but some farmer’s peak seasons are in the summer and spring depending on the crops they grow.

Laser cutting helps agriculturally by automating farm tasks, conserving irrigation water, soil analyses, and monitoring crops and livestock. The laser will process materials that will be used for heavy machinery and equipment for farmers, cutting the time and labor that is needed for manufacturing these parts. It will also speed up the harvesting and processing of crops, making everything more efficient for agriculture.

Benefits of Laser Cutting

Precision

Known for their precision technology, laser cutting machines increase productivity as they have a small margin of error at a +/- 0.1mm accuracy. These machines give precise final products that are exact to each customer’s specifications. The precision technology ensures that the surface of the metal being cut is not damaged during the process, it remains smooth throughout the whole process. Laser cutting is extremely consistent, you can trust that every product you need will be made exactly the same way each time, no matter how many of one product you order.

Sustainability

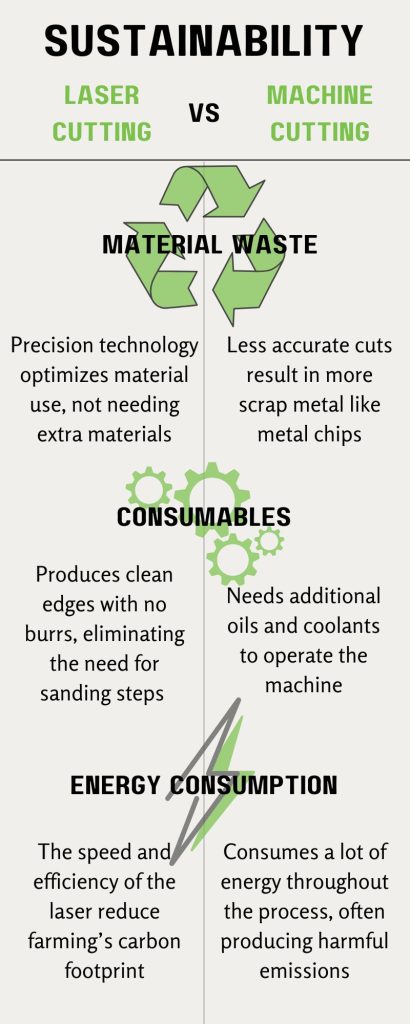

Unlike other metal-cutting techniques, laser cutting is a generally sustainable practice. Laser cutting reduces material waste, as its precision technology ensures that all material use is optimized. The machines used for laser cutting work automatically and don’t require as much manual labor to operate, making these machines much safer than other metal-cutting machines. They also promote less energy consumption, as the efficiency and speed of laser cutting take up less energy compared to other methods. Less material waste and energy-efficient machines can reduce the carbon footprint of farming, making the whole process more sustainable.

Cost-Effectiveness

Using a laser to cut metal is more cost-effective and durable than other machine-cutting techniques. Lasers can create intricate cuts efficiently and make a more durable product, meaning there are no downtimes or material waste that could increase the cost. The low maintenance and low operating costs make the price for laser-cut materials less expensive than materials made using other machine-cutting methods.

Customization

Laser cutting offers many versatile products and can adapt to a wide range of materials. Edge Metalworks can cut a variety of sheet metals, including steel, aluminum, bronze, copper, and brass. Laser-cutting technology can cut complex designs with ease as they are easily compatible with computer-aided design (CAD) systems that allow for more precision and efficiency. Once the sheet metal is cut, it can then be formed into custom components that will complete your project, bringing everything together.

Applying Laser Cutting to Agriculture

Machinery

Laser cutting creates improved machinery for agricultural processes. The sheet metal used for these processes needs to be cut at different thicknesses. Agriculture machinery bodies use sheet metal that is 1.5mm-15mm thick and the interior framing and components use metal that is 1mm-4mm thick. The main equipment that uses this sheet metal are tractors, harvesters, and planters.

Irrigation Systems

Irrigation is the process of supplying controlled amounts of water to crops to help them grow with the use of tubes, pumps, and sprays. Laser cutting allows for materials to be precisely cut for intricate parts of irrigation systems like drip lines, fittings, and emitters. Irrigation systems may also require precision cuts for tubing to allow for controlled water delivery.

Structures

Enhancing the durability of the metals that are cut, laser cutting increases the performance value of agricultural structures. The parts made will reinforce agricultural buildings, increasing the structure’s longevity. Structures that benefit from laser-cut metal include silos, fences, and storage units.

Equipment

Laser cutting provides functional and safe equipment for farmers to use. Equipment used in agriculture is generally made from stainless steel and galvanized aluminum. These metals are used to make steel sheets, tubes, and structural products for equipment. Laser-cutting technology creates precise holes and cuts in these materials, which will increase the accuracy of the equipment.

Choose Edge Metalworks for Your Laser Cutting Needs

Edge Metalworks will treat you like a partner, supplying you with quality laser-cut parts that will give you an advantage over your competitors. We invest in top-of-the-line technology to continuously give the best products to manufacturers in multiple industries. We pride ourselves in our customer service, we are committed to providing quality parts and services that will exceed our customer’s expectations. Contact one of our skilled technicians to begin our partnership.