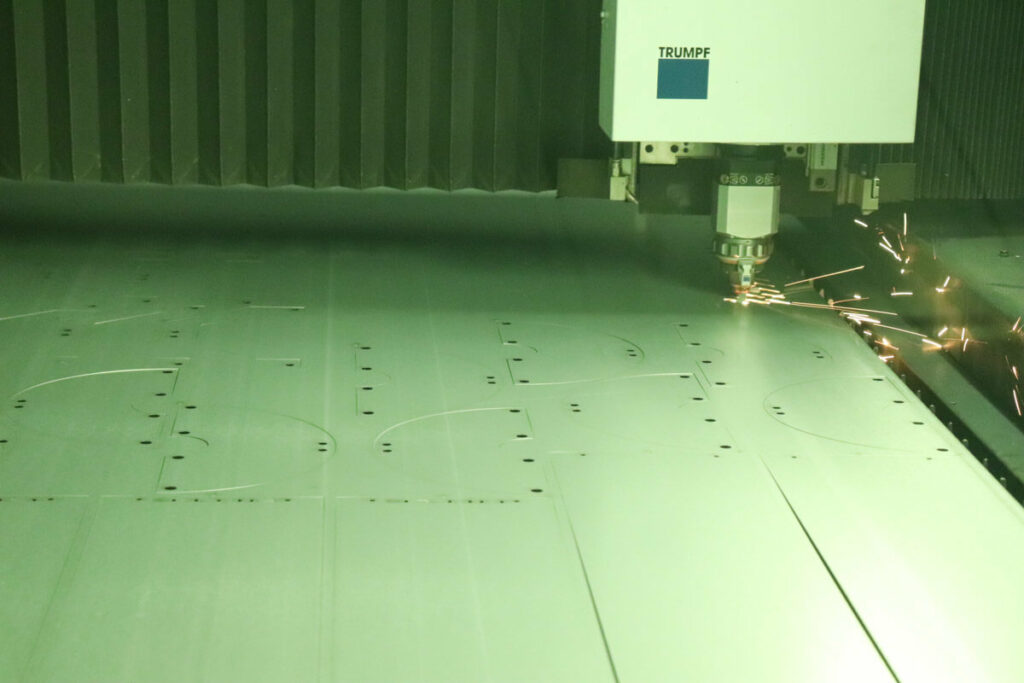

Laser-cutting is a vital technique used to help manufacture farming equipment. The agricultural industry is always growing, and farmers need durable, precise equipment to ensure all processes work smoothly and safely. Farming is a major industry in Pennsylvania, and equipment manufacturers rely on laser-cutting at Edge Metalworks, so we can provide them with the pieces they need to meet their farming season demands. Manufacturers like Horning Manufacturing utilize our services to laser-cut parts for their manufacturing and spare parts needs. Our technology is used to create parts that are used in skillfully built equipment for automated farming tasks. Below, I’ll explain the advantages of laser-cutting for manufacturing farm equipment.

Precise Equipment

Laser-cutting allows for the production of more efficient farm machinery due to its precision technology. It creates parts with tight tolerances, which is important for the reliability of complex farming equipment. In my experience, quality cut parts make for easier welding, improving the accuracy of welded parts that must be able to withstand high loads. It also creates more precise equipment, improving their overall performance.

Durability

Agricultural equipment must endure harsh conditions while remaining durable. The Northeast often has harsh weather that farm equipment will have to work through. Laser-cutting makes it easier to fabricate the durable materials needed for farming equipment so they can withstand the harsh conditions and frequent use. Our technology allows for minimal heat distortion, ensuring the materials stay strong even after being cut. I’ve seen it help manufacture various machinery components, including the pallets, walking wheels, sprockets, and more, to ensure the machine is durable.

Versatility

The versatility of laser cutting meets the demands of the Northeast’s farm manufacturing. We can cut various types of metals of various thicknesses. Farm equipment mainly uses carbon steel, stainless steel, galvanized steel, and aluminum. The versatility of laser cutting allows for complex designs, enabling the development of advanced farming equipment, specifically tractors and harvesters. Our CAD software allows for consistency, ensuring each versatile piece of the same design is cut to exact specifications with no defects.

Fast Turnaround Time

The efficiency of our lasers allows for a quicker turnaround time for completed parts. The laser has fast cutting speeds, reducing the production cycle for more efficient turnaround times. Farming demands are often on time-crunches, so having a fast production time is crucial. I’ve seen manufacturers come to Edge Metalworks for parts because they ran out of wear parts that they kept in stock. This is when fast turnaround times really matter.

Reduced Costs

Laser cutting reduces costs in many ways. It eliminates the need for expensive tooling, reduces labor costs with the automation it provides, and generates less material waste. With the precision in the lasers, there will be less scrap metal, so you’ll be spending less money on raw material costs. With Edge Metalworks, efficient laser-cutting leads to lower costs for new equipment and makes it more accessible for farmers.

Agricultural Equipment that Benefits from Laser-Cutting

Multiple kinds of modern farming equipment in Pennsylvania benefit from using laser-cut parts. Heavy machinery uses flat complex parts made from laser-cutting that are welded together. Below are some of the most common equipment that benefit from laser-cutting:

Tractors

Tractors need laser-cut parts, specifically in their frame and chassis, as they must be able to support heavy attachments. The custom attachments on tractors will also need precise laser-cut parts to improve performance. Our lasers can produce these custom designs quickly, so new attachments can be developed quickly. Laser-cutting ensures these parts are precise and strong, so they can reliably work. The detailed holes and shapes the lasers make will also allow for easy tractor assembly.

Harvesters

Havesters use sharp blades to properly and quickly cut a variety of crops. I’ve noticed that if a blade is even a little bit out of line, it can spell disaster for the machine and your wallet. Laser-cutting provides clean, smooth edges, so all crops will be cut properly. It makes cutting more efficient, so blade production is more cost-effective. The gears in both tractors and harvesters also need to be precisely made for smooth operations, as a misaligned gear can make the equipment perform poorly.

Irrigation Systems

Irrigation systems need highly accurate parts that only our laser cutting can provide. They benefit from our laser tube cutting services, as our lasers can cut tubes to exact measurements. This ensures no leaks occur and there is adequate water distribution. The pipes need the precision the lasers provide for proper water flow and accurate irrigation for Pennsylvania crops. Laser-cutting can also be used to create nozzles and sprinkler heads for irrigation systems to further optimize distribution.

Get Parts for Farming Equipment with Edge Metalworks

Edge Metalworks’ laser-cutting services are vital for manufacturing accurate, well-engineered farming equipment in the Northeast. We serve various industries to provide them with the detailed parts they need for their machinery. We offer a different level of professionalism for our services, ensuring everything is completed on time, to your exact specifications. If you’re ready to get started, contact us today.