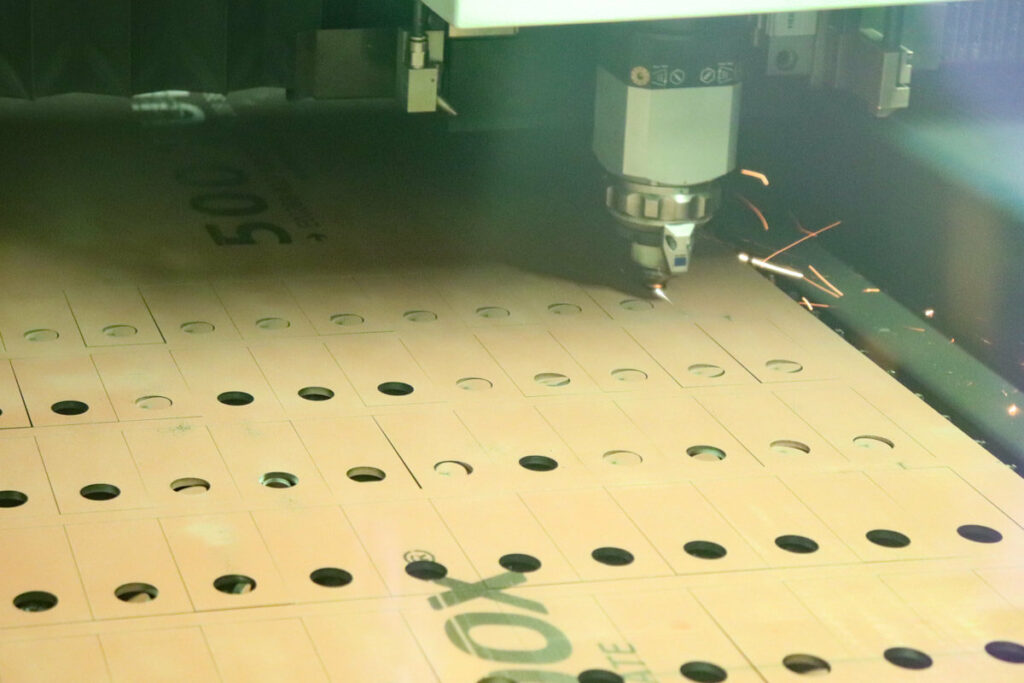

Laser-cut parts are vital machinery for many industries, particularly for being integrated into automated processes. As one of the most advanced innovations for material handling, laser cutting machines are great for automating production. Additionally, the parts cut from Edge Metalwork’s lasers can be integrated into machines for better automation, including machinery and robotic welding. Below, we’ve detailed what you need to know about how laser-cut parts are integrated into automated processes.

Why Do We Use Laser-Cut Parts in Automated Processes?

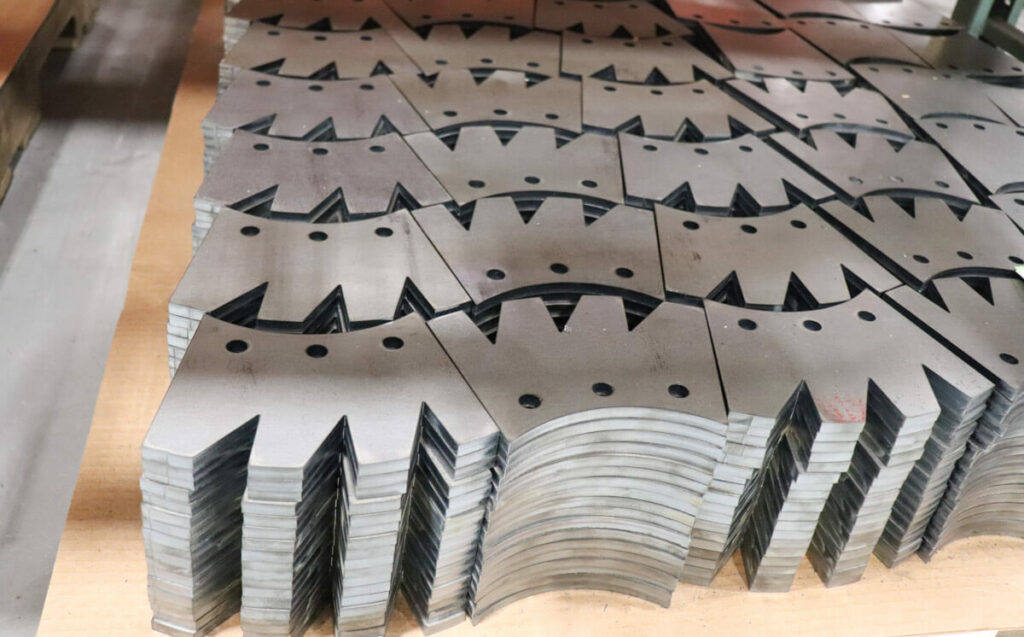

Laser-cutting improves efficiency, precision, and speed for machinery. Automated processes require precise repeatability, so the machinery needs to be made with parts that are exactly the same. The kind of precision that is required for these processes can only be made by laser-cutting machines and parts. In our experience, using laser cutting contributes to a smarter, more streamlined process for automation.

Laser-Cut Parts for Automated Machinery

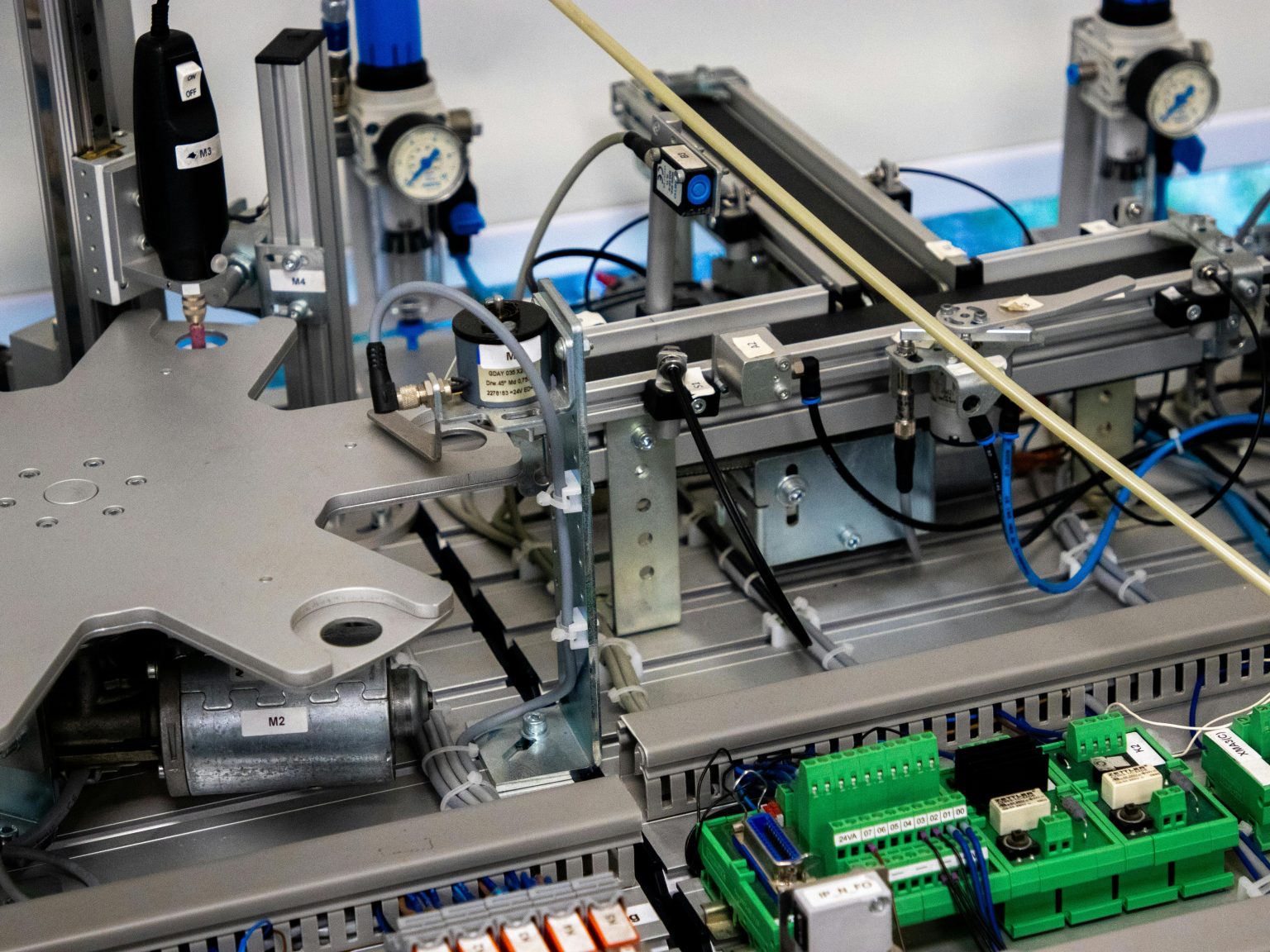

Automated machinery uses laser-cut parts because they are cheaper to produce and easier to integrate into equipment that requires precision. A laser-cutter provides parts to automate material loading, unloading, and parts handling to further streamline processes. Laser-cut parts are vital in creating machinery components, due to their ability to meet the specific needs of projects. Our parts meet the diverse needs of the machinery industry with their ability to cut through different metals with different thicknesses.

How Laser Cutting Improves Automated Machinery

Consistency is crucial for automated production, so we can produce complex shapes that are exactly the same. They improve automated machinery because lasers measure the accuracy of cut parts in real time, so they can detect any issues early on in production. Lasers also allow for the use of CAD software for precise control of cutting dimensions to the exact parameters you need.

Laser-Cut Parts for Robotic Welding

For processes like robotic welding, we’ve noticed parts need the consistency of laser-cutting to allow for precise welds and accurate fabrication. Also, laser-cut parts allow robotic arms to consistently load and unload parts into fabrication bays. The robotic arms can also be integrated with laser-cutting to automate material handling processes.

How Laser Cutting Improves Robotic Assembly

Conventional robotic welding systems lack flexibility. We’ve found that the use of lasers makes the machine more adaptable, allowing it to complete a wide range of welds. Laser-cutting is so precise that robot welders and robot assembly machines can easily assemble and fabricate anything you are manufacturing. Laser-cut parts used in tandem with robotic fabrication systems increase production speeds and make the process more efficient.

Edge Metalworks Has All Your Metal Laser-Cutting Needs

At Edge Metalworks, our laser-cutting processes can work with a variety of metals and thicknesses in a wide range of industries. We can cut pieces perfectly to your specifications. Our team offers laser-cutting, laser tube cutting, and forming services for your material handling needs. We have a specialized focus on manufacturing to provide you with precise, high-quality parts in a timely manner. Contact us to get started today.